News

-

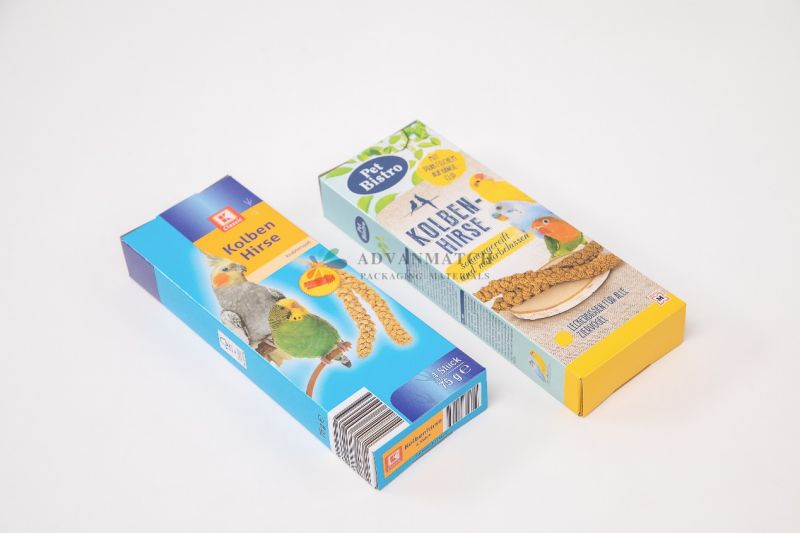

Why is paper cardboard packaging the best choice?

Firstly, paper cardboard packaging is an environmentally friendly choice. With the increasing awareness of environmental protection, cardboard packaging, as a renewable and recyclable material, has significant environmental advantages. The cardboard box is made of pulp, which is produced from ren...Read more -

What are the types of food packaging bags – how much do you know?

We see a variety of food packaging bags emerging in the market, mainly food packaging bags. For ordinary people, they may not even understand why a food packaging bag needs so many types. In fact, in the packaging industry, according to the type of bag, they are also divided into many bag types. ...Read more -

What are the types of materials used in paper packaging boxes?

Paper packaging boxes belong to the common types of packaging in paper product packaging printing. But how much do you know material of paper packaging? Let us explain to you as follows: Materials include corrugated paper, cardboard, gray base, white cardboard, and special art paper. Some also us...Read more -

Aluminum foil packaging, a rising star in food packaging

1911 was an important milestone in the history of world food packaging. Because this year was the debut year of aluminum foil in the field of food packaging, and thus began its glorious journey in the field of food packaging. As a pioneer in aluminum foil packaging, a Swiss chocolate company has ...Read more -

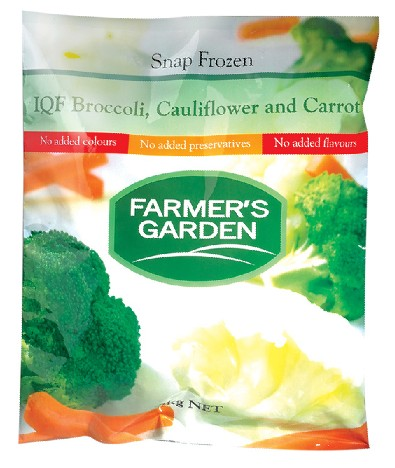

Knowledge Lecture Hall – Frozen Food Packaging

With the arrival of summer, the hot weather has made people pay more attention to the freshness and safety of food. In this season, frozen food has become the preferred choice for many families and consumers. However, a key factor in maintaining the quality and taste of frozen food is high-qualit...Read more -

A comprehensive list of various paper box packaging structures, really useful! Episode3

Design of Plate Packaging Structure The disc packaging box structure is a paper box structure formed by folding, biting, inserting, or bonding around the cardboard. This type of packaging box usually has no changes at the bottom of the box, and the main structural changes are reflected in the ...Read more -

A comprehensive list of various paper box packaging structures, really useful! Episode 2

2. Bottom structure of tubular packaging boxes The bottom of the box bears the weight of the product, therefore emphasizing firmness. In addition, when filling goods, whether it is machine filling or manual filling, simple structure and convenient assembly are the basic requirements. There are se...Read more -

A comprehensive list of various paper box packaging structures, really useful! Episode1

In the entire printing and packaging industry, color box packaging is a relatively complex category, as many things do not have standardized processes due to different designs, structures, shapes, and processes. Today, I have organized the structural design of common color box packaging single pa...Read more -

Packaging knowledge: Paper gift box classification, common structures, and production processes

Paper box packaging is largely used to promote and beautify products and enhance their competitiveness through its exquisite design and decoration. Due to the fact that the shape and structural design of paper boxes are often determined by the shape characteristics of the packaged goods, there ar...Read more -

How do the PVDC high barrier flexible packaging products apply to? Part 3

3、 Advantages of PVDC composite membrane: The development and application of PVDC composite membrane is a great production change in the field of PVDC reference. Compare the current circulation of high-temperature cooking resistant composite membrane on the market: A. Comparison between PVDC...Read more -

How do the PVDC high barrier flexible packaging products apply to? Part 2

2、 Specific application of PVDC composite membrane in China: China has started the practical application of PVDC resin since the early 1980s. First, the birth of ham sausage introduced PVDC film into China. Then Chinese companies broke the blockade of the United States and Japan on this technol...Read more -

Common bag/pouch types for food packaging bags

1.Three-sides sealing bag This is the most common type of food packaging bag. The three-sides sealing bag has two side seams and one top seam bag, and its bottom edge is formed by horizontally folding the film. This type of bag can be folded or not, and when folded, they can stand upright on the...Read more