1、 Polyester vacuum bag:

Polyester is a general term for polymers obtained by polycondensation of polyols and polybasic acids. It mainly refers to polyethylene terephthalate (PET), polyester (PET) vacuum bag. It is a colorless, transparent and glossy vacuum bag. It is a vacuum bag material made of polyethylene terephthalate as raw material by extrusion and biaxial stretching. It has excellent mechanical properties, high rigidity, hardness and toughness, puncture resistance, friction resistance, high and low temperature resistance, chemical resistance, oil resistance, air tightness and fragrance retention. It is one of the commonly used composite vacuum bag substrates. It is commonly used as the outer material of cooking packaging, with good printing performance.

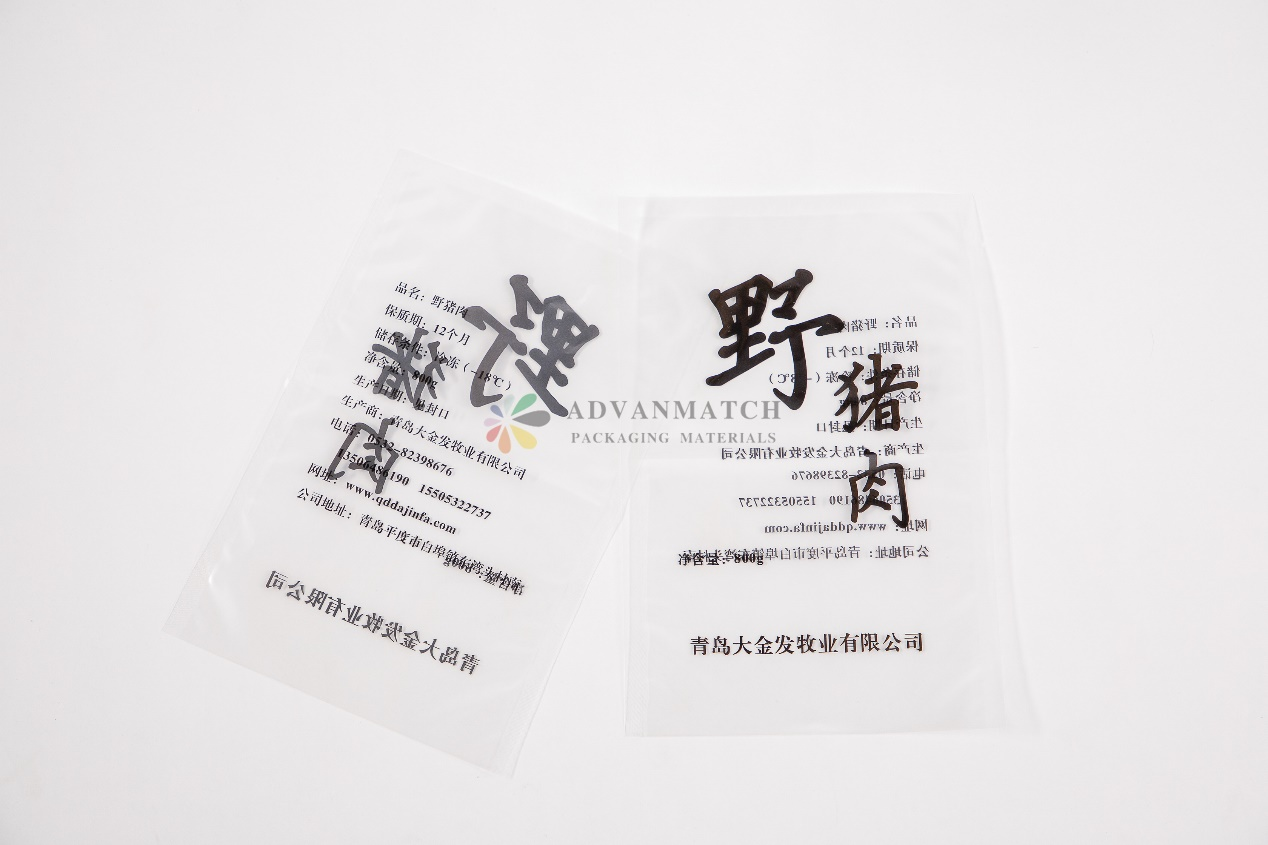

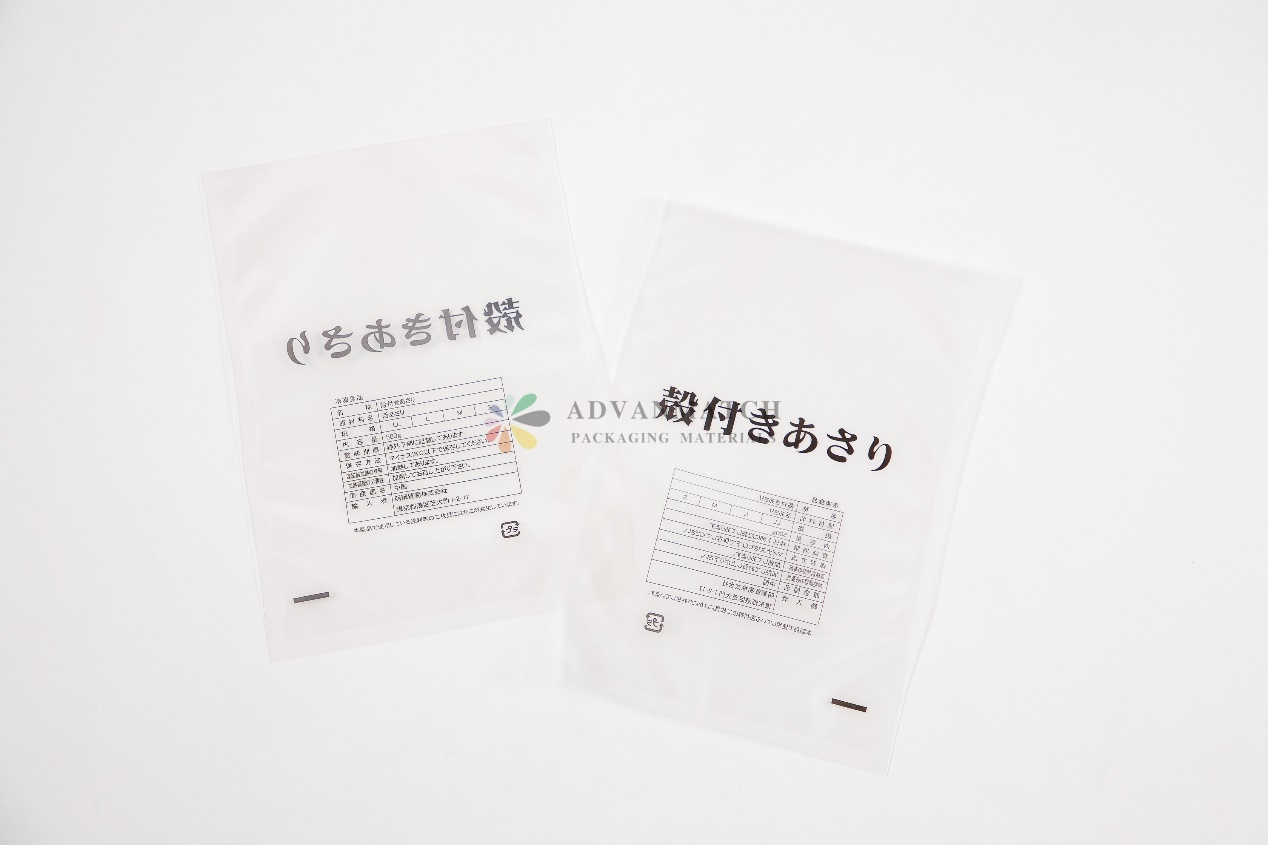

2、 Nylon vacuum bag:

Nylon (PA) vacuum bag is a very tough vacuum bag with good transparency, good gloss, high tensile strength and tensile strength. It also has good heat resistance, cold resistance, oil resistance and organic solvent resistance. It has excellent wear resistance, puncture resistance, soft and excellent oxygen resistance. It is suitable for packaging hard goods, such as greasy food, meat products, fried food, vacuum packaged food, cooked food, etc. On the basis of nylon vacuum bag, nylon composite bag and multi-layer coextrusion vacuum bag with higher performance can be derived. Nylon composite bags are mainly composed of pet/pe, ny/pe, ny/pvdc, pe/pvdc and pp/pvdc. The main difference is that in terms of technology, composite bags are generally composed of base materials, laminated adhesives, barrier materials, heat sealing materials, printing and protective layer coatings. The multi-layer coextrusion vacuum bag is mainly composed of nylon, which is composed of PA, EVOH, PE, PP, tie and other resins, and adopts a symmetric or asymmetric composite structure. Due to the addition of PA and EVOH, the barrier to oxygen and flavor, composite peel strength, environmental resistance and fresh-keeping storage period of the multilayer film are greatly improved. It has the characteristics of no pollution, high barrier, strong function, low cost, small capacity ratio, high strength and flexible structure. It makes the production process of food packaging materials pollution-free. 3. PE vacuum bag: Polyethylene (PE) is a thermoplastic resin prepared by polymerization of ethylene. The transparency is lower than that of nylon. It has a firm hand feel and a crisp sound. It has excellent air and oil resistance and fragrance retention properties. Not suitable for high temperature and cold storage. The price is cheaper than that of nylon. It is generally used for ordinary vacuum bag materials without special requirements.

3、 Aluminum foil vacuum bag:

Aluminum plastic composite vacuum packaging bag (pet/al/pe or pet/ny/al/pe or pet/ny/al/cpp), the main component is aluminum foil, opaque, silvery white, anti-gloss, good barrier, heat sealing, optical opacity, high temperature, low temperature, oil resistance and fragrance retention; Non-toxic and tasteless; Flexibility, etc. It is suitable for moisture-proof, light proof and vacuum packaging of large precision mechanical equipment, chemical raw materials and pharmaceutical intermediates. Four layers structure is adopted, which has good water and oxygen separation function. Aluminum foil vacuum bags are widely used in food, electronics, chemical and other industries. Since the raw materials of aluminum foil are relatively expensive, the cost of vacuum will also be relatively high. The above is the introduction of common materials and characteristics of vacuum packaging bags summarized by Qingdao Advanmatch packaging. I believe that many friends will have a general understanding when choosing their own product packaging bags after reading it.

Post time: Aug-30-2022