News

-

How do the PVDC high barrier flexible packaging products apply to? Part 1

1、 Performance and application of PVDC: The international plastic industry is used to use the physical quantity of permeability to indicate the difference in performance and the materials with oxygen permeability below 10 are called high barrier materials. 10~100 are called medium barrier mater...Read more -

Differences and characteristics between co-extruded film and composite film

In the film processing, one kind of raw material is extruded onto another kind of film that has been made or onto different kinds of films that have been made and adhesive is used to bond together to form multilayer films. This product is called composite films. Co-extruded film has most of the c...Read more -

Definition and characteristics of multilayer co-extruded film

First of all, the multilayer co-extrusion resistance diaphragm is a plastic film. In the field of plastic products, we usually refer to flat plastic products with thickness less than 0.2 mm as plastic films, those with thickness between 0.2 and 0.7 mm as plastic sheets and those with thickness gr...Read more -

Application and Characteristics of EVOH Multilayer Co extruded Film

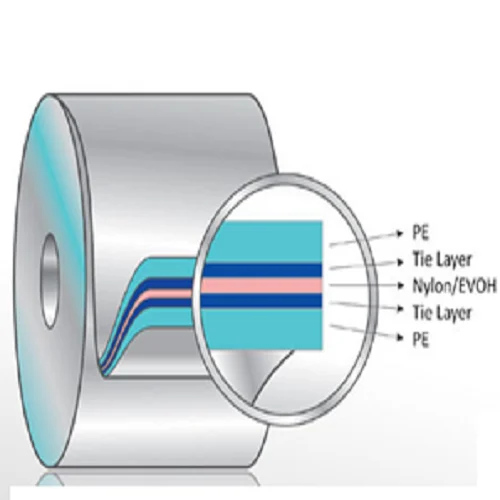

Multilayer co extruded film is generally a kind of film with excellent barrier performance, mechanical performance, tensile forming performance and heat-sealing performance, which is made of a variety of high barrier raw materials through the co extrusion composite processing process. It does not...Read more -

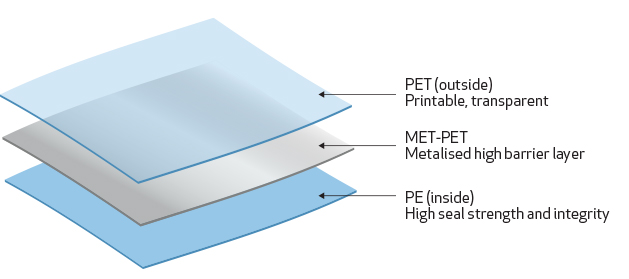

Structure and Functions of EVOH Multilayer Co extruded Film

The structures of multilayer co-extruded films can be divided into two categories, namely symmetric structure (A/B/A) and asymmetric structure (A/B/C). At present, the barrier films in China are mainly composed of 5 layers, 7 layers, 8 layers and 9 layers. The symmetrical structural layer of mult...Read more -

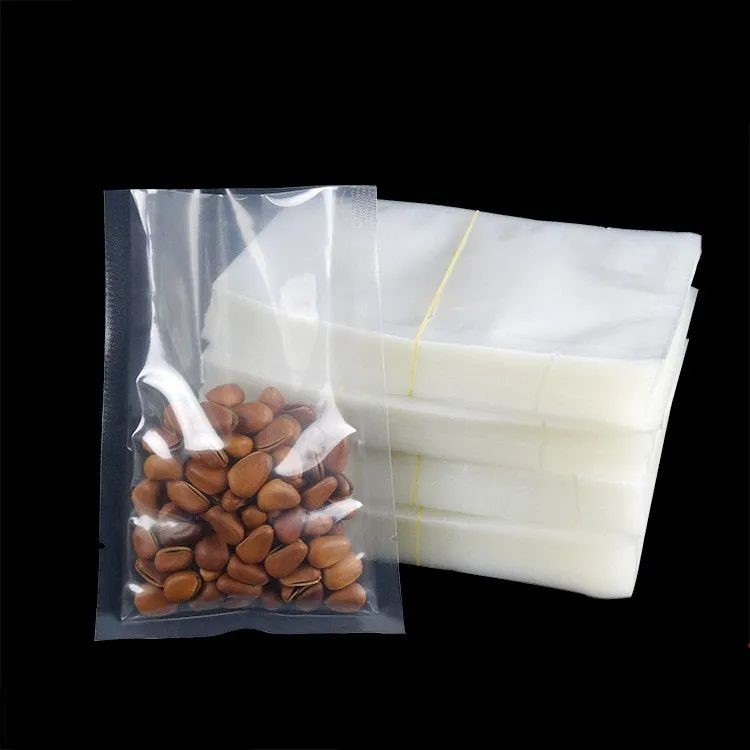

Inspection knowledge of food packaging bags

Food packaging bags belong to one of the food packaging materials testing categories, mainly made of plastic materials, such as polyethylene packaging bags, polypropylene packaging bags, polyester packaging bags, polyamide packaging bags, polyvinylidene chloride packaging bags, polycarbonate pack...Read more -

What should we pay attention to in the design of food packaging bags?

In addition to providing protection for food, the design of food packaging bags should also take into account the aesthetic feeling and can arouse the appetite of consumers. Let’s take a look at what aspects should be paid attention to in the design of food packaging bags. 1. Color Problem...Read more -

The main problems of flexible packaging in future development direction (automatic packaging) Episode4

6、 Heat-seal leakage Leakage is due to the existence of some factors, so that the parts that should be combined by heating and melting are not sealed. There are several reasons for leakage: A: Insufficient heat-sealing temperature. The heat-sealing temperature required by the same packaging ma...Read more -

The main problems of flexible packaging in future development direction (automatic packaging) Episode3

4、 Hot sealing extrusion PE problem During the heat-sealing process of the composite film, PE is often extruded and stuck to the heat-sealing film. The more it accumulates, the more it affects normal production. At the same time, the extruded PE oxidizes and smokes on the heat-sealing die, givi...Read more -

The main problems of flexible packaging in future development direction (automatic packaging) Episode2

2、 Friction coefficient problem Friction in packaging is often both drag and resistance, so its size should be controlled within an appropriate range. Coils for automatic packaging are generally required to have a small internal friction coefficient and a suitable external friction coefficient. ...Read more -

The main problems of flexible packaging in future development direction (automatic packaging) Episode1

Packaging machines can be divided into vertical and horizontal ones, and vertical ones can be divided into continuous (also known as roller type) and intermittent (also known as palm type) ones. Bagging can be divided into three side sealing, four side sealing, back sealing, and a number of lines...Read more -

The modelling design of paper carton packaging Epsode3

8. Design of portable paper packaging box This method is mainly to increase the handle of the package and design it into a portable package, so that the overall shape of the package will be greatly changed. This kind of full colors printed paper packaging box must be designed according to the wei...Read more