Concerning the factories introductions, quotations, MOQs, delivery, free samples, artworks design, payment terms, after-sale services etc. Please click FAQ to have all the answers you need to know.

Click FAQs

Click FAQsWholesale Coffee Sachet Bag Manufacturer – Vacuum packaging bags – Advanmatch Detail:

Vacuum sealing is a process of extracting the air inside a bag, pouch, or package before sealing it. This method involves (manually or automatically) placing items in a plastic film package, removing air from inside and sealing the package.

The intent of vacuum packing is usually to remove oxygen from the bags to extend the shelf life of foods and, with flexible package forms, to reduce the volume of the contents and package.

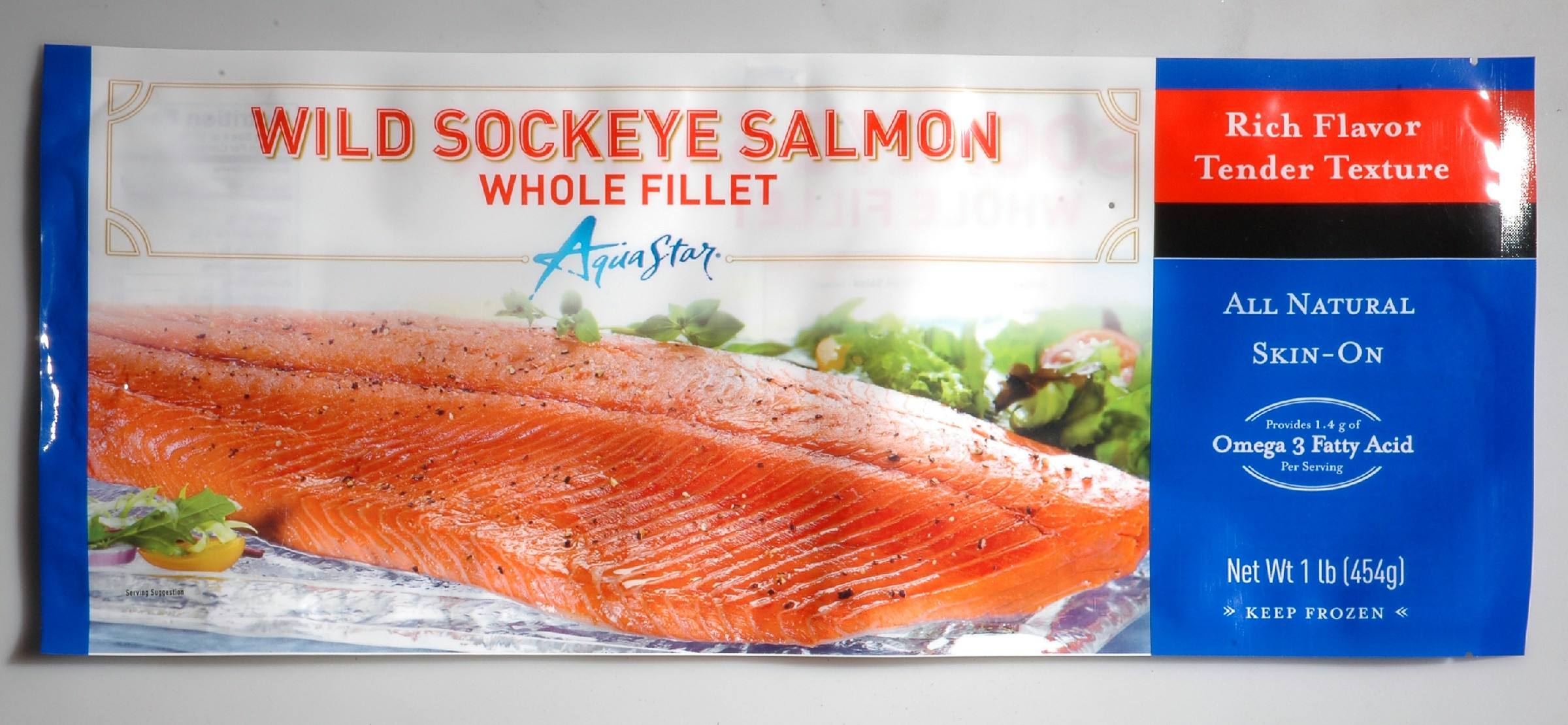

Vacuum packaging reduces atmospheric oxygen, limiting the growth of aerobic bacteria or fungi, and preventing the evaporation of volatile components. It is also commonly used to store dry foods over a long period of time, such as cereals, nuts, cured meats, cheese, smoked fish, coffee, and potato chips (crisps). On a more short-term basis, vacuum packing can also be used to store foods or paste such as cooked red bean paste, cheese, vegetables, meats, smoked salmon and semi-liquids because it inhibits bacterial growth.

Vacuum packing greatly reduces the bulk of non-food items. For example, clothing and bedding can be stored in bags evacuated with a domestic vacuum cleaner or a dedicated vacuum sealer. This technique is sometimes used to compact household waste, for example where a charge is made for each full bag collected.

For delicate food items that might be crushed by the vacuum packing process (such as potato chips), an alternative is to replace the interior gas with nitrogen. This has the same effect of inhibiting deterioration due to the removal of oxygen.

Vacuum sealed packaging protects from oxidation, spoilage, and corrosion, which can dramatically extend product shelf-life. This method is mainly used in the food industry and the medical industry. Qingdao Advanmatch provides exquisite custom printing service in vacuum packaging bags in different sizes & ensure your products stay fresh until it’s time for the customer to consume them. We are consistently delivering quality vacuum bags in custom sizes, material structures and printing artwork to customers, always will.

Product Shelf-life

Our fast-food pouches are air-tight and made of high-barrier materials. These features help preserve the flavors and freshness of the food product for much longer than other types of packaging.

Food Safety

We use quality materials that are recommended for food storage by the FDA. They are sterile, BPA-free, and do not leach any chemicals into the food products or alter their flavors.

Convenience

Qingdao Advanmatch Packaging food pouches are lightweight and compact. They can easily be stored in a freezer or carried along to outdoor events like camping trips. This offers your consumers convenient utility.

All of our packaging products are fully customizable to suit your branding needs including custom full-color printing, customized sizes, customized material structure etc. Please contact us to get a customization quote!

Color-match: Printing according to confirmed-sample or Pantone Guide Color number

What is a vacuum pouch?

Vacuum pouches are laminated film bags of can be vacuumed. Vacuum packing is a method of packaging that removes air from the package via vacuum sealing machine. Generally speaking, laminated film is used to have a tight fit to the contents.

What are the advantages of vacuum packaging?

Vacuum sealing makes for efficient, organized packaging. Vacuum sealed food takes up less room in your refrigerator or freezer and allows you to easily see the foods you are storing. Vacuum sealing provides food an air-tight environment, preventing the crystals that cause freezer burn from forming on your food.

What’s your material structure of vacuum packaging bags?

Our vacuum bags are engineered using films by using combinations of Nylon (PA) and Polythene (PE). This gives them a high moisture and oxygen barrier and so are ideal for extending shelf life of products.

What’s the applications of vacuum packaging bags?

bone in meat / ribs, bone in chicken, mussels, shellfish, pistachios, Fresh Meat, Fish, Poultry,

Sausages and Cured Meats, Cooked Meats, Cheese, Bread, Sauces and Soups, Boil in the Bag and Pasteurization, Ready Meals and Non-food etc.

What is your turnaround time on vacuum packaging pouches?

Once your artwork has been approved, your vacuum packaging pouches will be produced in 15 working days.

Product detail pictures:

Related Product Guide:

We stick with the theory of "quality first, company first, steady improvement and innovation to satisfy the customers" for the management and "zero defect, zero complaints" as the quality objective. To perfect our provider, we deliver the items together with the fantastic good quality at the reasonable value for Wholesale Coffee Sachet Bag Manufacturer – Vacuum packaging bags – Advanmatch , The product will supply to all over the world, such as: Egypt, Brazil, Manchester, With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in this field and other industries. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success! We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!